DIRECTED ENERGY

DEPOSITION

3D PRINTING

INNSTEK.COM

Safety and Service, Always our Priority

InssTek: Pioneering Additive Manufacturing Solutions for Metal Applications

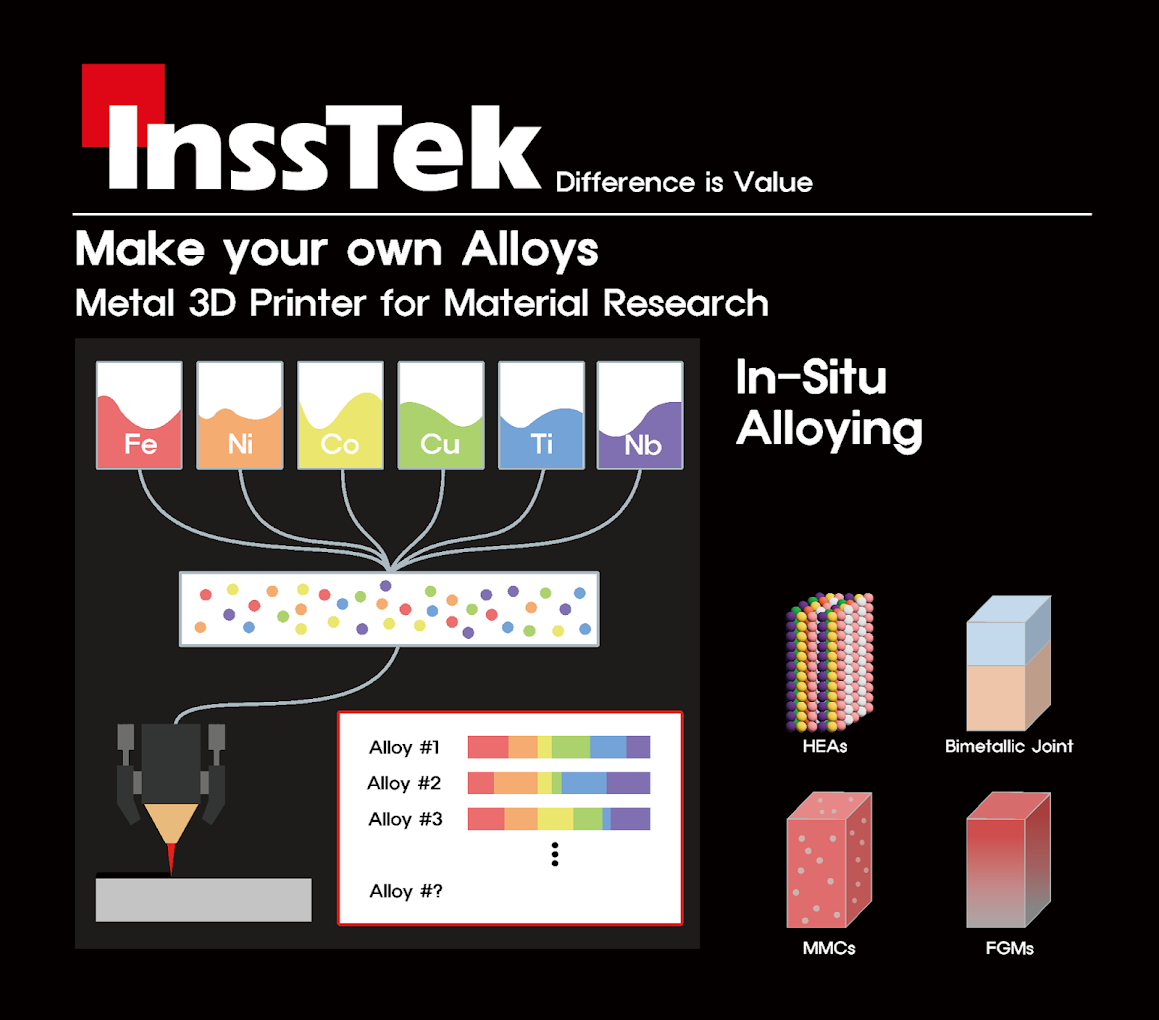

InssTek, Inc. is a world-renowned pioneer in Additive Manufacturing (AM), with a strong focus on Directed Energy Deposition (DED) technology. The company offers comprehensive solutions for Metal AM, leveraging its expertise in multi-material 3D printing, alloy research, and porous coating for artificial joints. From product design to production, InssTek has developed all the necessary technologies in-house, ensuring a seamless and user-friendly experience for customers utilizing its metal printers.

Our Main Technologies at InssTek

Satisfaction Guaranteed with InssTek's Innovative Additive Manufacturing Solutions

- DMT® Technology: Advanced technology enabling efficient and precise metal additive manufacturing.

- CVM Powder Feeding System: A state-of-the-art system designed for optimal powder delivery and consistency during the printing process.

- AM-Module System: Modular system that enhances flexibility and scalability in additive manufacturing applications.

- AM-CAM Software: Comprehensive software solution for managing and optimizing the entire additive manufacturing workflow.

Videos

- New Technology Zoom Optics & Moving Vision

- Zoom Optics

- Zoom Opic type AM-Module is the key solution to improve process efficiency and deposition quality. Since the lens magnification can be controlled with software, it is possible to change the lens magnification value during deposition.

- DMT Moving Vision

- The vision parts move vertically to increase the degree of shape freedom while maintaining optimal quality by continuously applying DMT technology. InssTek's simultaneous 5-Axis AM-CAM predicts the expected point of collision between the vision parts and the printed part and operates the vision part to avoid it.

- Video demonstrates the LFM-2 operation and how it works in your projects.

Multi-Material Rocket Nozzle(Full Ver.)

- A full video of the multi-material rocket nozzle manufacturing process!

- At the 1st International Conference on Advanced Manufacturing(ICAM) hosted by ESA and NASA,

- InssTek presented "Multi-Material Rocket Nozzle Manufacturing Process

- – From Material Research to Fabrication with DED(Direct Energy Deposition)" on the topic.

- In the future, DED technology will greatly contribute to the space industry,

- and check out InssTek's technological differentiation through the multi-material rocket nozzle video.

Metal AM(Additive Manufacturing) Technol…

- COMTES FHT specializes in applied research of metallic materials dealing with developments in the field of additive technologies at the experimental workplace.

- For research, Technologies and machines used DED (Directed Energy Deposition) metal 3D printer.

- The InssTek's MX-600 uses the Powder blown method, in which a powder that is entrained by an inert gas is injected into a laser-exposed area and used primarily for research purposes to advance the field of additive technology.

- ▶ https://www.comtesfht.com/additive-manufacturing

"InssTek: Your Trusted Partner for Direct Energy Deposition 3D Printing Solutions"

How We Are Different

At InssTek, we stand out in the additive manufacturing landscape through our unwavering commitment to innovation, quality, and customer-centric solutions. Our Direct Energy Deposition (DED) technology is designed for high precision and versatility, allowing for the creation of complex geometries with a variety of materials. We pride ourselves on our in-house developed technologies, ensuring that every aspect of our process, from powder feeding systems to software solutions, is optimized for peak performance and reliability. Additionally, our dedicated support team provides personalized assistance, ensuring that customers receive tailored solutions that meet their specific needs.

Why Choose InssTek's Direct Energy Deposition 3D Printing

- Versatile Material Options: Our DED technology supports a wide range of metals and alloys, enabling diverse applications across industries.

- Enhanced Efficiency: The DED process minimizes waste and allows for rapid production, helping to reduce overall manufacturing costs and time.

- Scalability: InssTek’s systems are designed to accommodate varying scales of production, making it suitable for both prototyping and large-scale manufacturing.

- Superior Precision: With our advanced DMT® Technology, you can achieve intricate designs with high accuracy, ensuring superior end-product quality.

- Comprehensive Solutions: We provide end-to-end services, from initial design to final production, streamlining the entire process for our clients.

Choose InssTek for cutting-edge DED 3D printing technology that enhances your manufacturing capabilities while ensuring exceptional quality and support. For more information, visit

InssTek.

Types of Directed Energy Deposition (DED):

- Laser Metal Deposition (LMD)

- Additive Manufacturing with Directed Energy

- Metal 3D Printing

- Laser Engineered Net Shaping (LENS)

- Powder-fed Additive Manufacturing

- Wire-feed Additive Manufacturing

- Electron Beam Additive Manufacturing (EBAM)

- 3D Printing with Energy Deposition

- Advanced Metal Deposition

- Focused Energy Deposition

Types of 3D Printing Companies:

- Additive Manufacturing Firms

- Metal 3D Printing Services

- Industrial 3D Printing Solutions

- Laser-Based 3D Printing Companies

- Custom 3D Printing Providers

- Advanced Manufacturing Solutions

- 3D Printing and Rapid Prototyping

- Hybrid 3D Printing Technology

- Precision 3D Printing Companies

- 3D Printing for Aerospace and Automotive

Combined:

- DED 3D printing service

- Laser metal deposition companies

- Advanced metal 3D printing providers

- Electron beam additive manufacturing services

- Metal additive manufacturing experts

- Wire-fed 3D printing technology

- LMD 3D printing solutions

- Directed energy metal deposition suppliers

Get a Free Quote Today!

Contact Us

Our Company

InssTek, Inc. is a leading Korean company specializing in Directed Energy Deposition (DED) technology. Here's a brief overview:

About InssTek, Inc.

- Founded: 2001

- Headquarters: Daejeon, South Korea

- Specialization: Advanced metal 3D printing using Directed Energy Deposition (DED) technology.

Key Features of InssTek

- DED Technology: InssTek is recognized for its proprietary DED technology, which uses a high-power laser to melt metal powder or wire, allowing for precise and high-quality metal part production.

- Industrial Applications: Their technology is widely used in industries such as aerospace, automotive, defense, and energy for the repair, prototyping, and manufacturing of metal components.

- Customization: InssTek offers tailored solutions, from small-scale machines to large industrial systems, catering to specific needs like component repair and hybrid manufacturing.

- Global Reach: With a growing presence in the international market, InssTek has established itself as a key player in the metal additive manufacturing industry.

Notable Products

- MX Series: High-performance metal 3D printers designed for complex part production.

- iClad System: A specialized system for metal repair and coating applications using DED technology.

InssTek continues to innovate in the field of metal 3D printing, making significant contributions to the advancement of additive manufacturing both in Korea and globally.